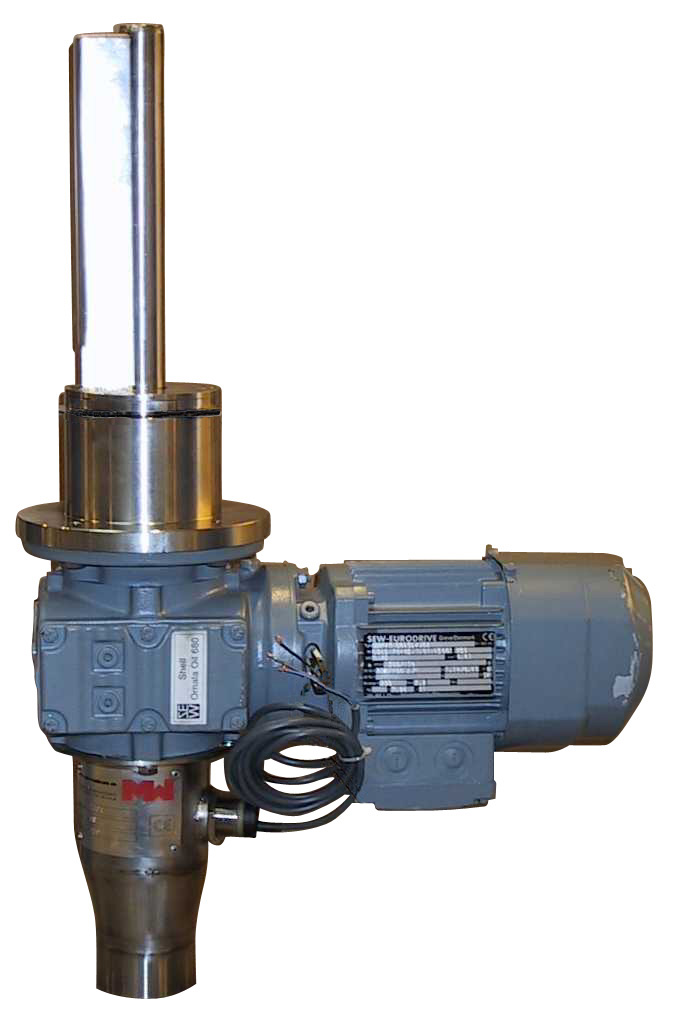

Air Slide Sampler (AS).

What’s the benefit?

- The design the AS does not reduce or hinder the material flow in the air slide, this allows the operation to be both efficient and easy to operate.

- Compared to a manual grab sample, the AS provides an automated sample and eliminates tedious and hazardous work.

What does it do?

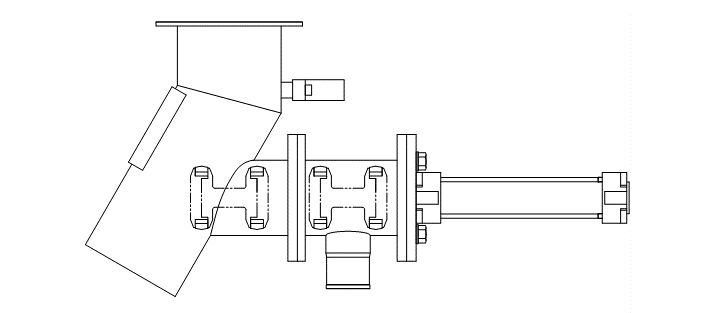

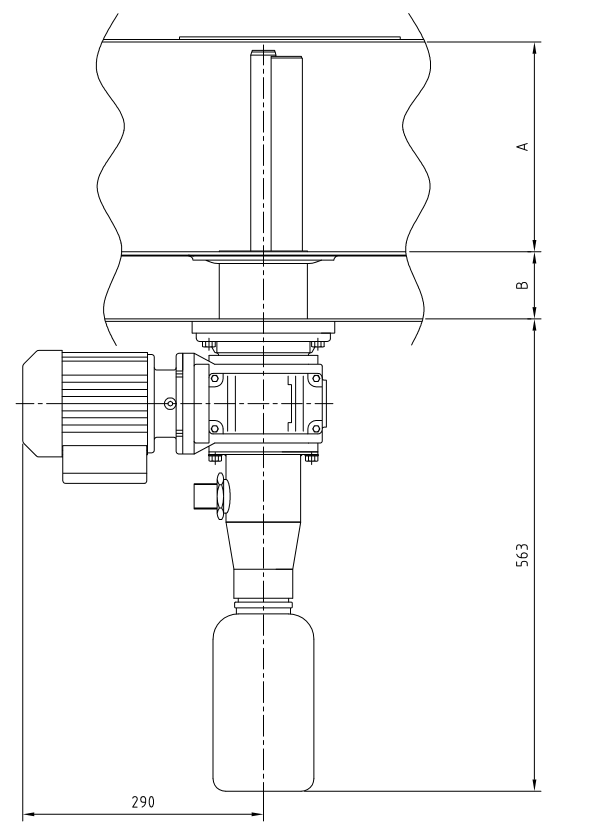

The Air Slide Sampler (AS) is designed for continuous or intermittent increment extraction of dry, non-sticky airborne powdered material ducted in horizontal or inclined air slides. The AS intersects ducted material, typically confined to a circular cross-section, in a linear increment transect.

How does it do it?

The AS has a rotating extraction tube provided with a longitudinal slot with an opening of 4 mm or as required. The tube is fastened in the hollow rotation axle in a way that extracted increments fall directly into the sample bottle. The small increment mass extracted per rotation allows for either continuous or semi-continuous sampling over a period of time. This results in an average composite sample. The AS capacities are dependent on slot opening and rotational tube speed.

In the intervals between extractions the rotating tube is parked with the slit into a protective guard, which is positioned opposite the material flow. The sampler is provided with an inductive sensor acting as combined speed monitor and position indicator.

What are the technical details?

The sampler is manufactured from stainless steel and designed for working in a non-condensed environment.

Drive unit: Geared brake motor

Voltage: 230V/ 50Hz (or as required)

Power: 0.25 kW

Sampling tube: Stainless Steel AIS304.

Options

The AS can be supplied with a local control cabinet

Nota Bene 1

The AS operates under the assumption that the cross-section of the ducted material is of sufficiently uniform composition, allowing it to be sampled by a diagonal transect only. The degree to which an air slide sampler can obtain a fit-for-purpose representativity status is dependent upon the specific heterogeneity characteristics of the ducted material. M&W offers customers a facility for quantitative assessment of the performance following one or several types of analysis such as variographic or replicate analyse based on the customer’s material.