Introducing M&W Engineering

Bridging theory, engineering and practical applications for 50 years.

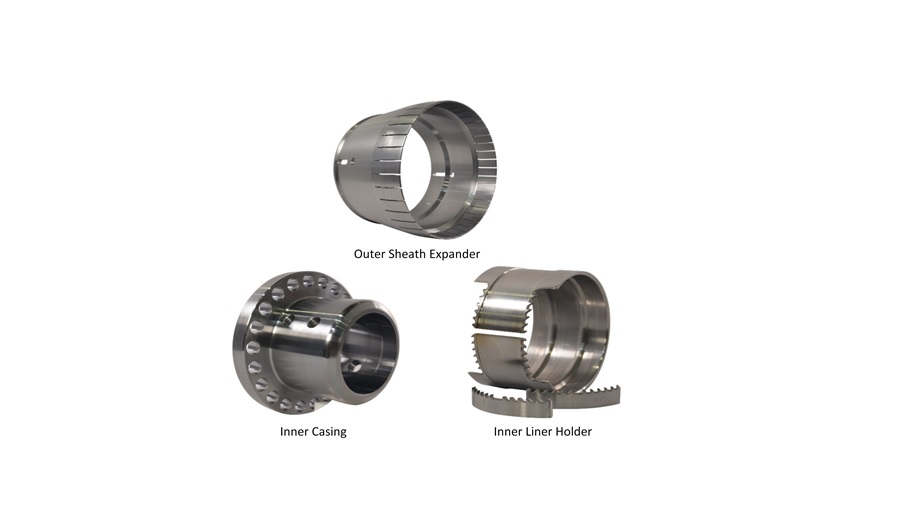

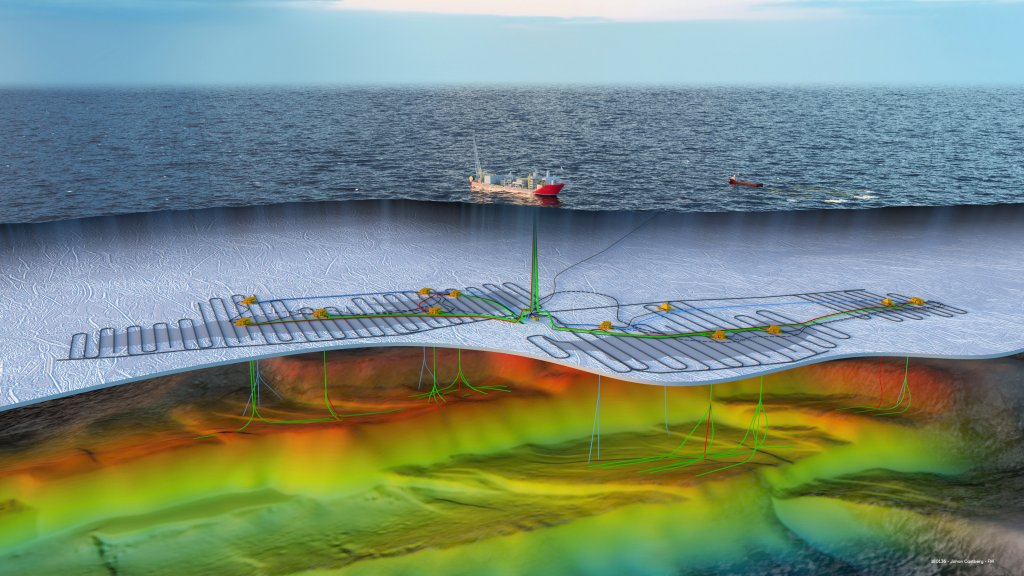

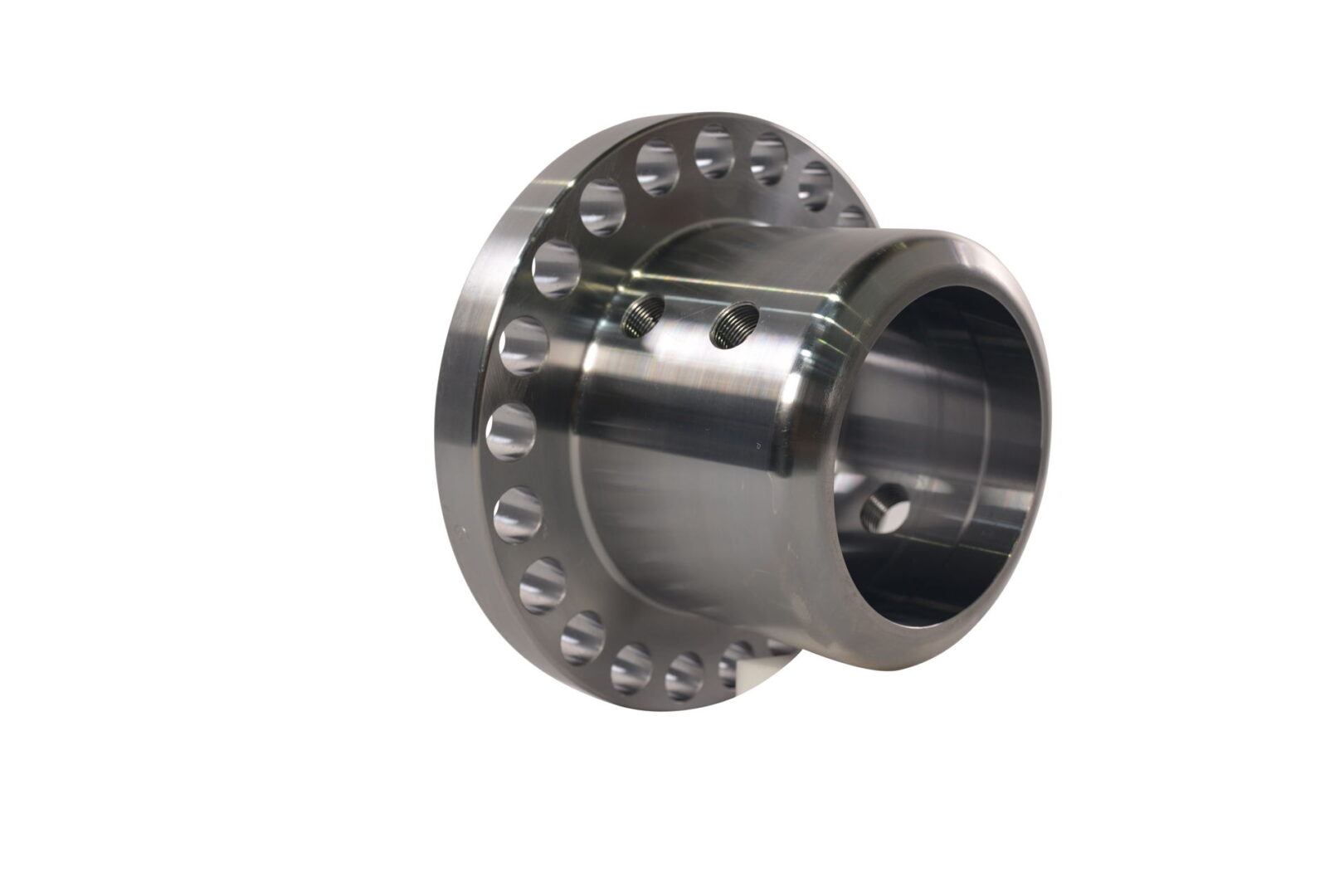

M&W Engineering offers customers a wide range of customized products for protection, storing, separation, mixing, cleaning, measuring and processing for sectors such as pharma/healthcare, food, industry, transportation, energy and oil & gas.

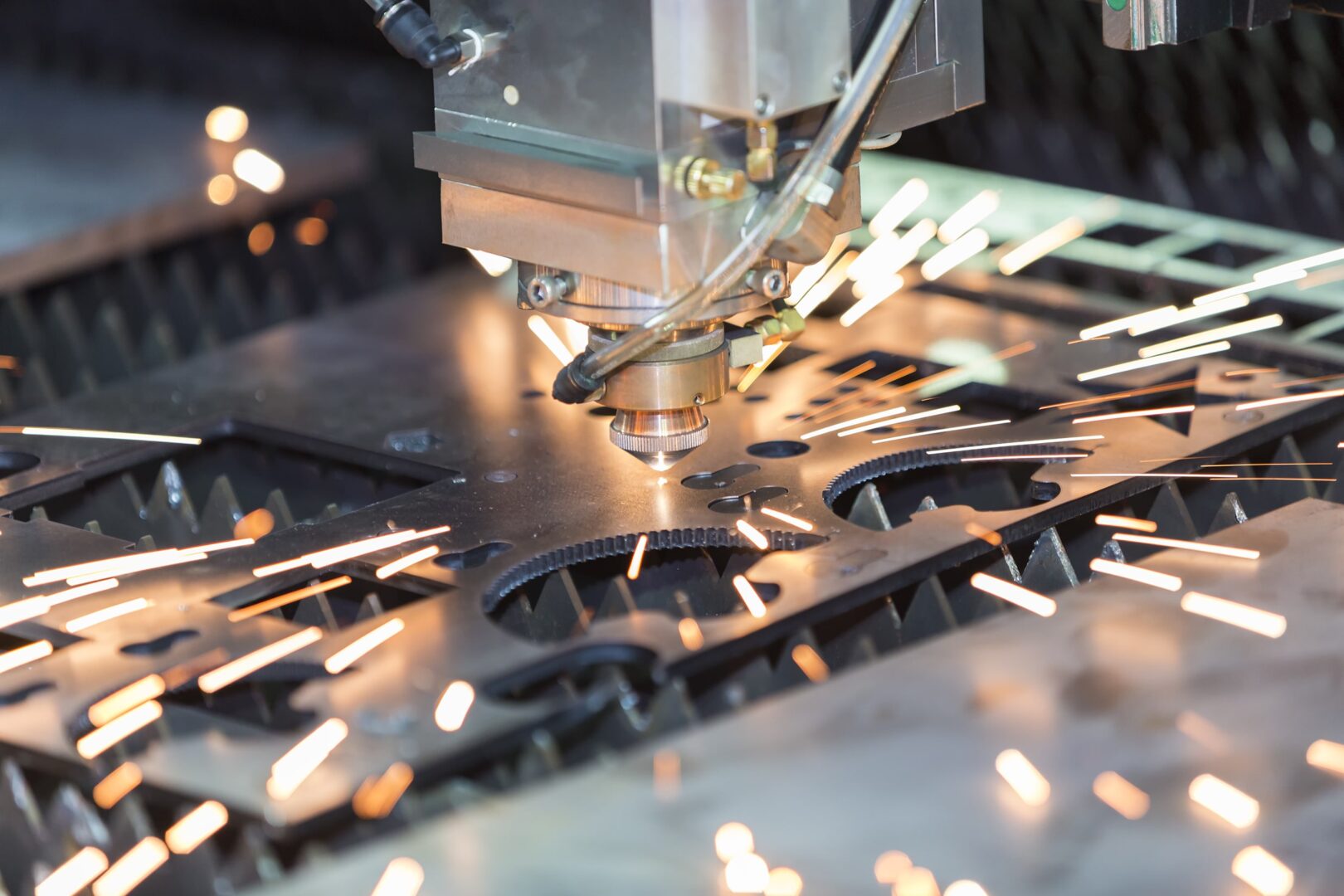

We combine 50 years of experience as a sub-contractor of machined parts, welding and metal work and electrical/automation services with our prototype experience, project management and engineering skills.

If you are looking for a manufacturing partner with a complete production value-chain in addition to strong documentation, calculation and testing skills, in other words your external project leader M&W Engineering is the right partner for you.

We offer high quality and flexibility, work with a wide range of different materials and accommodate both small and large orders.

Contact information.

M&W Engineering.

Design, manufacturing and documentation

Mechanical, electrical and automation

Two Welding Workshops (1,500 m2)

Electrical Workshop (400 m2)

ISO 14001 Compliant

ISO 45001 Compliant

We are located in Kvistgaard, 30 km north of Copenhagen, Denmark with 4,000 m2 of facilities including 4 modern production facilities divided between machinery, welding and electrical workshops (3,000 m2) along with our engineering and administrative offices (1,000 m2). We employ 40+ mechanical and electrical engineers, machinists, welders and industrial electricians.

Our engineers primarily work with the development of special machines and measurement instruments. We have a deep insight in analysis of mechanical, electrical and thermodynamic systems. Furthermore we are knowledgeable in measurement theory and techniques. Finally, we are accustomed to provide extensive documentation and quality control.

Products.

M&W Engineering offers a wide range of different products for protection, storing, mixing, cleaning, measurement and processing to a variety of highly professional industrial partners in sectors such as pharma/healthcare, food, industry, transportation, energy and oil & gas. For examples of our different product categories see below:

Our certificates.

Quality Management

Mark & Wedell is ISO 9001:2015 certified as quality management is an integral part of our business model. We implement this in practice by tracking the following three steps: quality planning, quality control and quality improvement.

Environment

Mark & Wedell has defined standards related to environmental management based on ISO-14001 which is the international standard that specifies requirements for an effective environmental management system (EMS). Our objective is to improve our environmental footprint as much as possible and thereby reducing energy consumption and pollution (waste, air, smell, and noise). Each year we produce environmental accounts including data regarding: Consumption of: Energy (natural gas, power and oil), raw materials (steel, aluminum, copper, plastic etc.) and ancillary materials (gas, refrigerant/lubricant, welding electrodes etc.) as well as waste/ by-products (iron, steel, paper/cardboard, plastic, paint etc.) and air emissions from production. We comply with all regulatory requirements regarding environmental protection and pollution prevention and has received Environmental Approval by the municipality of Helsinore in Denmark.

Safety and working environment

Mark & Wedell has defined standards to provide a safe and healthy workplace based on ISO 45001 Occupational Health and Safety. By following this framework we endeavor to improve employee safety, reduce workplace risks and create better, safer working conditions. To ensure this in practice we have formed a Security and Health Committee with representatives from different parts of the organization including owner-representative. The Security and Health Committee meets 1-2 per annum to discuss and follow-up on potential safety and health issues or ad hoc when certain issues occur. In addition, the Danish Working Environment Authority inspects our production and administration facilities from time to time. Mark & Wedell has earned a green smiley (best category) as a result.

Other

Mark & Wedell is certified to participate in Achilles Utilities NCE (former Sellihca) EU Tender platform.

ISO 9001:2015

Most recent audit: November 2019

Original cycle start date: 26 May 2000

Environmental Approval (Miljøgodkendelse)

Issued September 2019 by the Muncipality of Helsinore, Denmark

ATEX certificate approval

Issue date: 10 Jan 2017

Achilles Utilities NCE

M&W approved supplier to utilities in Nordic and Central Europe

The Danish Working Environment Authority

Green smiley shows that The Danish Working Environment Authority has not found any violations of the health and safety legislation at Mark & Wedell.