Cross-Belt Sampler (CBS).

What’s the benefit?

The Cross-Belt Sampler (CBS):

- Is a cost-effective sampling solution.

- Is customized to the client’s specific installation and type of material at no, or very limited additional costs.

- Is easy to install almost anywhere along a conveyor belt.

- Is well suited as a retrofit sampler and can be integrated on existing conveyor belts.

- Eliminates the need for hazardous and manual grab sampling thereby increasing employee safety.

- Saves time and money allowing for sampling without belt stoppage.

- Can be modified to remove identified unwanted magnetic/metallic material from the conveyor belt.

- Meets ISO, ASME, GOST international standards for granular bulk materials.

What does it do?

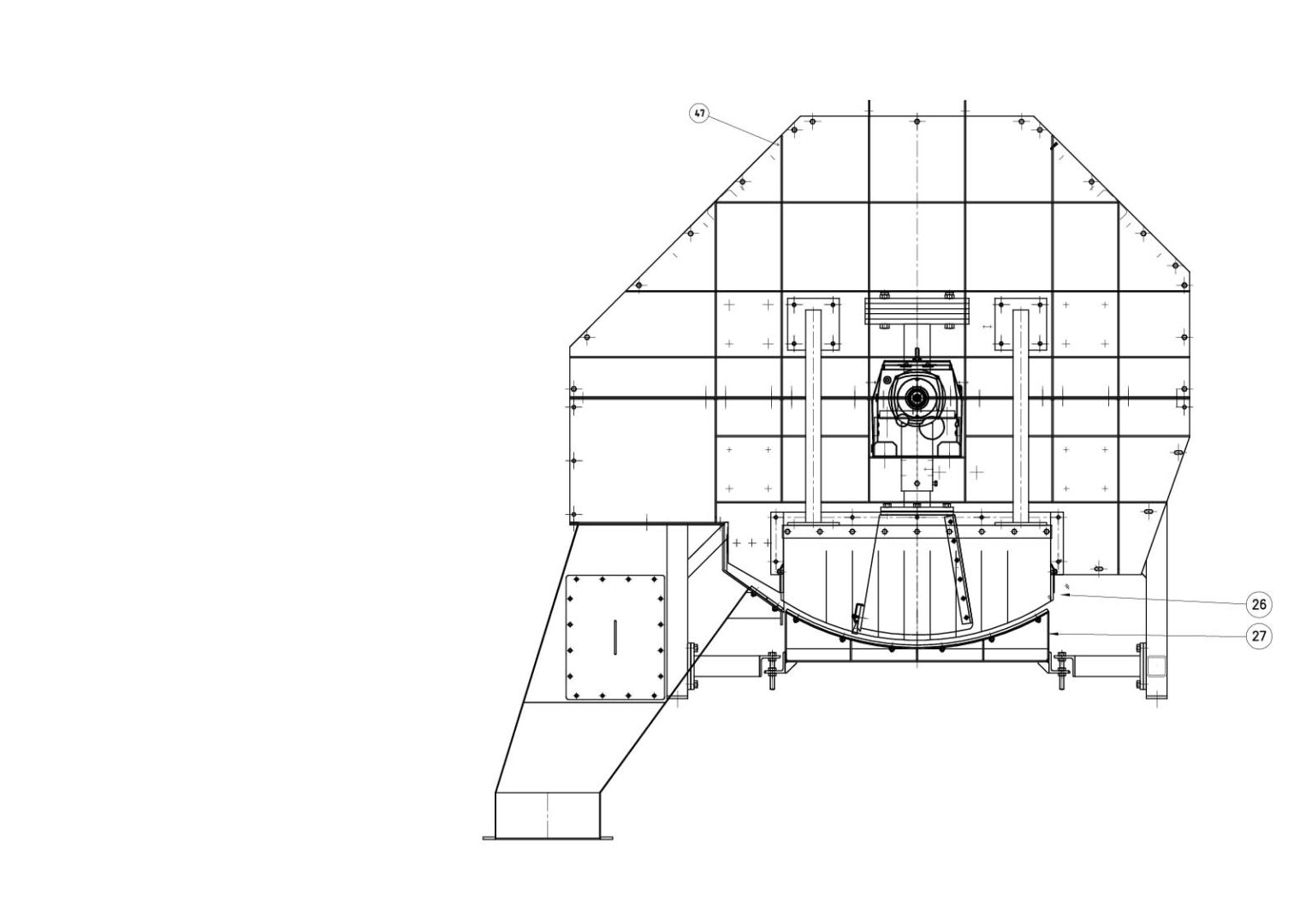

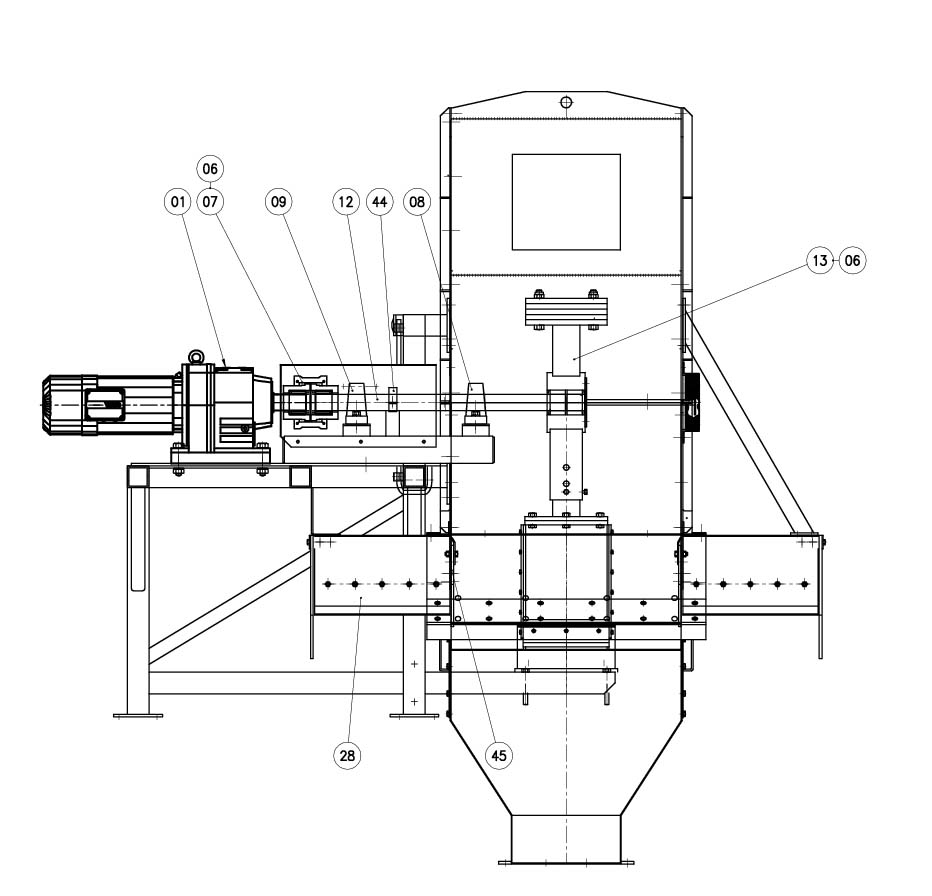

The Cross-Belt Sampler (CBS) is designed to take an increment/cut from bulk materials being conveyed on a conveyor belt. The CBS includes a fully enclosed housing that covers all moving parts thereby reducing spillage and increasing safety.

How does it do it?

The sampler consists of a rotating counter-weighted sample cutter which moves in a 360-degree rotation perpendicular to the material direction. The sample cutter is driven by a gear brake motor and a guiding section is supporting the conveyor belt. The cover house is equipped with hatches allowing easy inspection, cleaning, and maintenance.

When automatically or manually triggered, the sample cutter is accelerated by the electric motor to the designated velocity. It cuts through the material stream on the conveyor belt in a circular motion, following the supported shape of the belt. The conveyer belt is supported and guided by a pair of inclined rollers or guiding plates which ensure that the sample cutter remains in maximal contact with the belt throughout the entire cut. Furthermore, a flexible scraper is installed to ensure collection of all “fines”. The increments are then delivered to sample containers or to optional secondary sub-systems. After leaving the cut zone, the sample cutter is slowed down to allow the collected increment to fall into the outlet chute. Internally located skirts after the cut zone close the gap to the conveyor belt to prevent spillages.

What are the technical details?

- Sample cutter: Stainless Steel (AISI304), with a carbon steel counterweight to reduce the dynamic effects on the support and cutter.

- Support frame: Painted carbon steel

- Housing: Stainless Steel plates (AISI304)

- Gear Motor: SEW with brake or similar

- Sensors: Inductive type

The CBS is delivered with either a local control unit or/and is controlled by a M&W central control cabinet depending on concept and local conditions. The M&W central control cabinet consist of motor control center, circuit breakers, PLC-system and man-machine interface.

Options

The M&W central control cabinet can exchange signals with the client’s control system.

Nota Bene 1

The CBS can be calibrated with respect to the client’s material(s) and local sampling conditions. M&W offers clients a facility for quantitative tests assessing the performance of the sampler on the client’s own material(s), following one or several types of tests, the Replication Experiment test, or variographic characterisation of process sampling performance.

Nota Bene 2

Many generic cross-belt samplers such as a standard Hammer Sampler have difficulties obtaining representive samples due to non-optimal designs. The M&W Cross-belt sampler design evolving during 40 years of design development in combination with its guided rollers and scrapers makes it a state-of-the-art cross-belt sampler.