Dividing Plant (DP).

What’s the benefit?

The Dividing Plant (DP):

- Automatically divides bulk material into several representative samples of equal size and with minimum interference from the operator.

- Is a flexible sampler which can be applied in different parts of the production line as the DP also comes in a mobile and easily transportable version (DP-M)

What does it do?

The Dividing Plant (DP) is designed for representative division of bulk materials with various particle sizes. The DP can be installed in conjunction with a sampling plant or as a standalone divider.

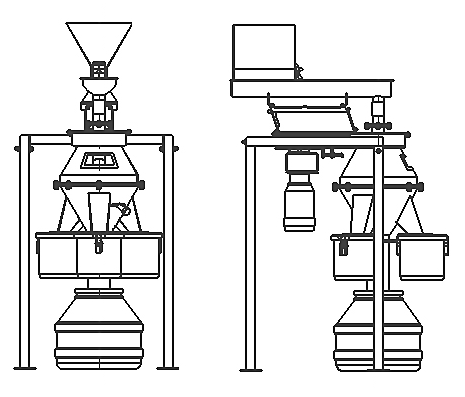

Variant 1:

The Dividing Plant-Stationary (DP-S) is stationary and is mounted to the floor.

Variant 2:

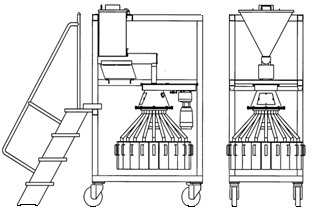

The Dividing Plant-Mobile (DP-M) is mobile and can be easily moved around in the facility. The DP-M comes with wheels and a hatch.

How does it do it?

The DP consists of a feed hopper, a Vibration Feeder (VF), a Rotary Tube Splitter (RTS), a supporting steel structure and several dust-proof sample buckets. The material is extracted from the feeding-hopper by a step-less adjustable vibration feeder and dosed into the RTS. In the RTS a drive unit rotates a dividing tube, from where the material stream is divided into the sample outlets.

What are the technical details?

Details to follow..

Options

The DP is delivered with a local control cabinet.

Nota Bene 1

The DP can be provided with any amount of sample outlets (within a range) that the customer requires.

Nota Bene 2

The DP has to be supplied with 400/230 VAC.