Front-Back Stream Sampler (FBSS).

What’s the benefit?

The Front-Back Stream Sampler (FBSS) is:

- Theory of Sampling (TOS)-compliant which gives every particle in the stream an equal probability to be included in the extracted increment.

- Designed to occupy less space, compared to the Cross Stream Sampler (CSS), making it well suited where space constraint is an issue.

- Equipped with less moving parts compared to other primary samplers.

- Thanks to a scalable design, the FBSS can cope with high volumes of moving bulk materials.

- Well suited for harsh environments and rough materials, as commonly seen e.g., in the mining industry.

- Usable as a secondary or tertiary sampler as part of a multi-stage sampling/sub-sampling system.

What does it do?

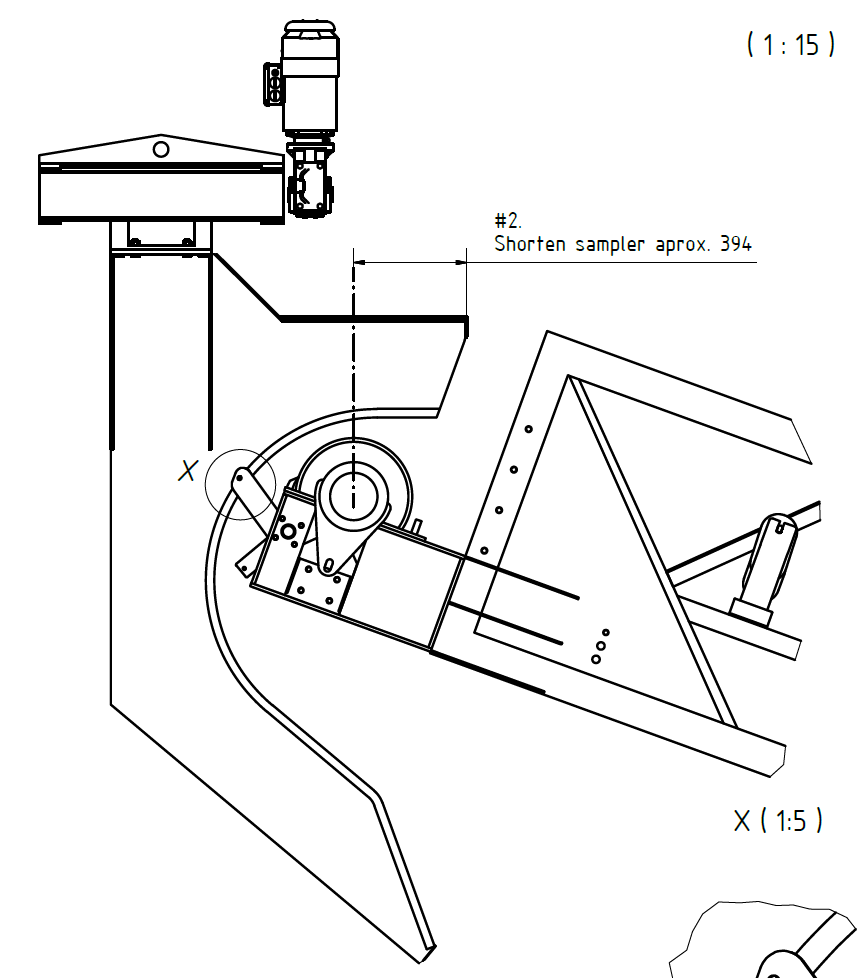

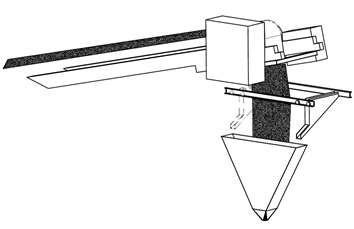

The Front-Back Stream Sampler (FBSS) is designed to extract a representative increment/cut by collecting a complete cross section of the free-falling bulk material at the discharge point of the conveyor belt. The FBSS operates within a “front-to-back” cutting motion across the falling stream and delivers the complete increment to a transverse outlet chute.

How does it do it?

The FBSS consists of a bucket cutter oriented parallel to the moving stream surface. The bucket is attached to a double rail carriage, located above the material flow. The motor control ensures that the cutter operates at a constant speed of up to 0.6 m/s when collecting increments from the falling material stream. Each time the cutter moves through the stream, front-to-back and back-to-front, an increment is continuously deposited in the outlet chute.

What are the technical details?

The particular design features are decided upon with respect to the specific material characteristics and the stream vectors involved. Considering the extreme density and toughness of some materials, the extraction is recommended as Hardox steel.

The conveyer belt can have a width between 500-2.500 mm.

Housing: Stainless Steel AISI 304/316 or painted carbon steel

Railing system: Stainless Steel AISI 304/316 or painted carbon steel

Carriage: Stainless steel AISI 304/316 or painted carbons steel with Hardox impact plate

Instruments: Inductive Position switches

Gear Motor: SEW or similar

The FBSS is delivered with either a local control unit or/and is controlled by a M&W central control cabinet depending on concept and local conditions. The M&W central control cabinet consist of motor control center, circuit breakers, PLC-system, and man-machine interface.

Options

1. The M&W central control cabinet can exchange signals with the client’s control system.

2. The FBSS can be delivered with an intermittant sampling option, extracting an increment after each crossing, dependent upon the client’s local setup and needs.