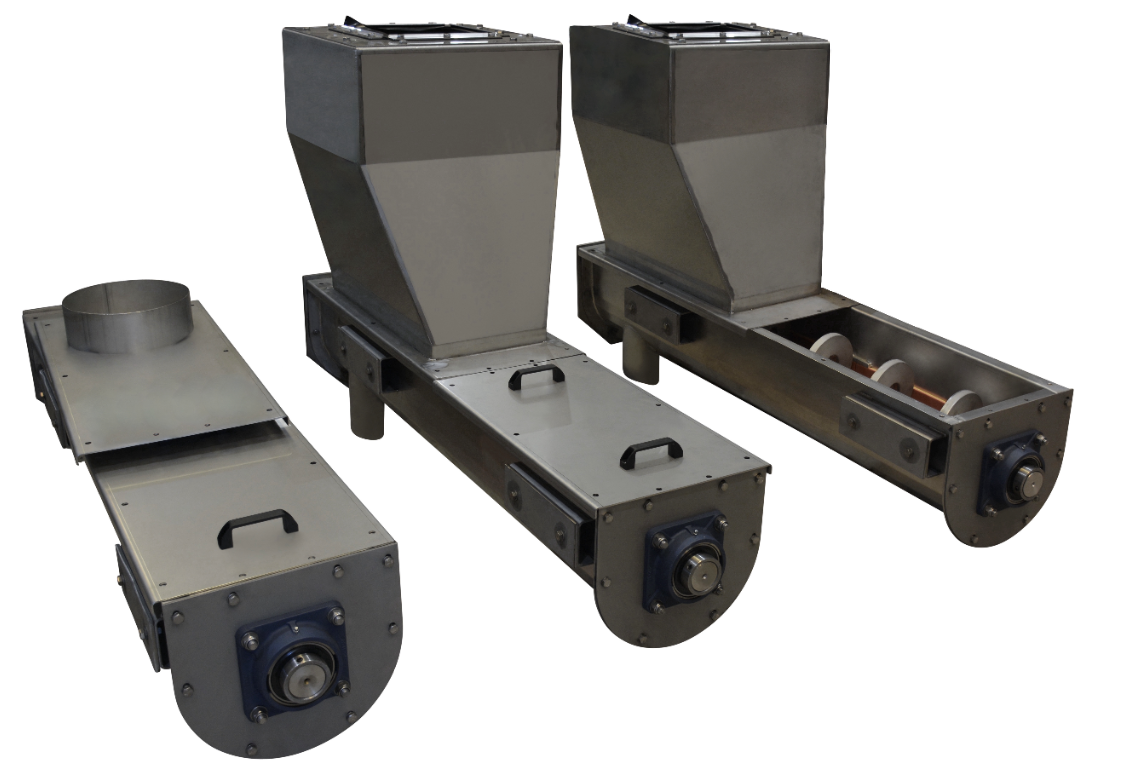

Screw Conveyor (SC).

#temlate whats_the_benefit

The Screw Conveyor (SC):

- Can transport material in a dust-free manner and is weatherproof.

- Is easy to install and require minimal maintenance.

- Can operate from vertical to horizontal angle.

- Is, unlike other transportation systems, guaranteed to have no spillage of material or production of dust, due to closed transportation.

What does it do?

The Screw Conveyor (SC) is used for transportation of bulk materials from A to B by rotation of a screw (the auger principle). The material is transferred in a tube that ensures no spillage of material. The SC provides accurate dosing for instance into a crusher or a divider. The SC can also be used to transport relatively small volumes of reject material from sample preparation back to the mainstream.

How does it do it?

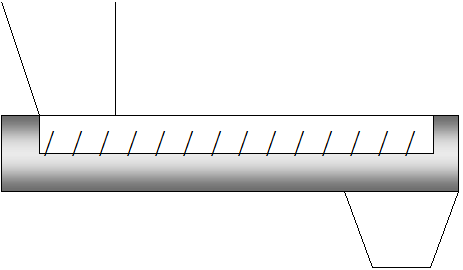

The SC consists of an inlet chute, a rigid outer tube, a screw mounted on a shaft, a geared motor and an outlet. The material enters in the inlet chute and is being transported by the screw blade to the outlet. The SC can transport material either horizontally or tilted upwards/downwards.

What are the technical details?

Drive unit: Geared brake motor

Voltage: 400/230V-50Hz or as required

Sensor: Rotation sensor

Length: 1 – 5 [m]

Housing: Stainless steel/painted mild steel

Inspection hatch(es): As shown on the drawing below

ATEX: According to customer request

The screw with shaft is supported by suitable bearings at both ends.

Options

1. The SC is also available in a ATEX version depending on requirement.

2. The SC can be delivered in a precision version to ensure extraction of very fine particles.

3. If necessary, in order to control the dosed amount of material, the speed can be varied by controlling the motor speed through a frequency converter.

4. The tube may be provided with an inner lining to increase wear resistance.

Nota Bene 1

The screw may in some cases be designed sufficiently ridged to work without a shaft.