Twin Roll Shredder (TRS).

What’s the benefit?

- The TRS has a solid design and very reliable performance.

- The TRS has low maintenance costs and low noise level.

- The TRS provides a unique self-cleaning action.

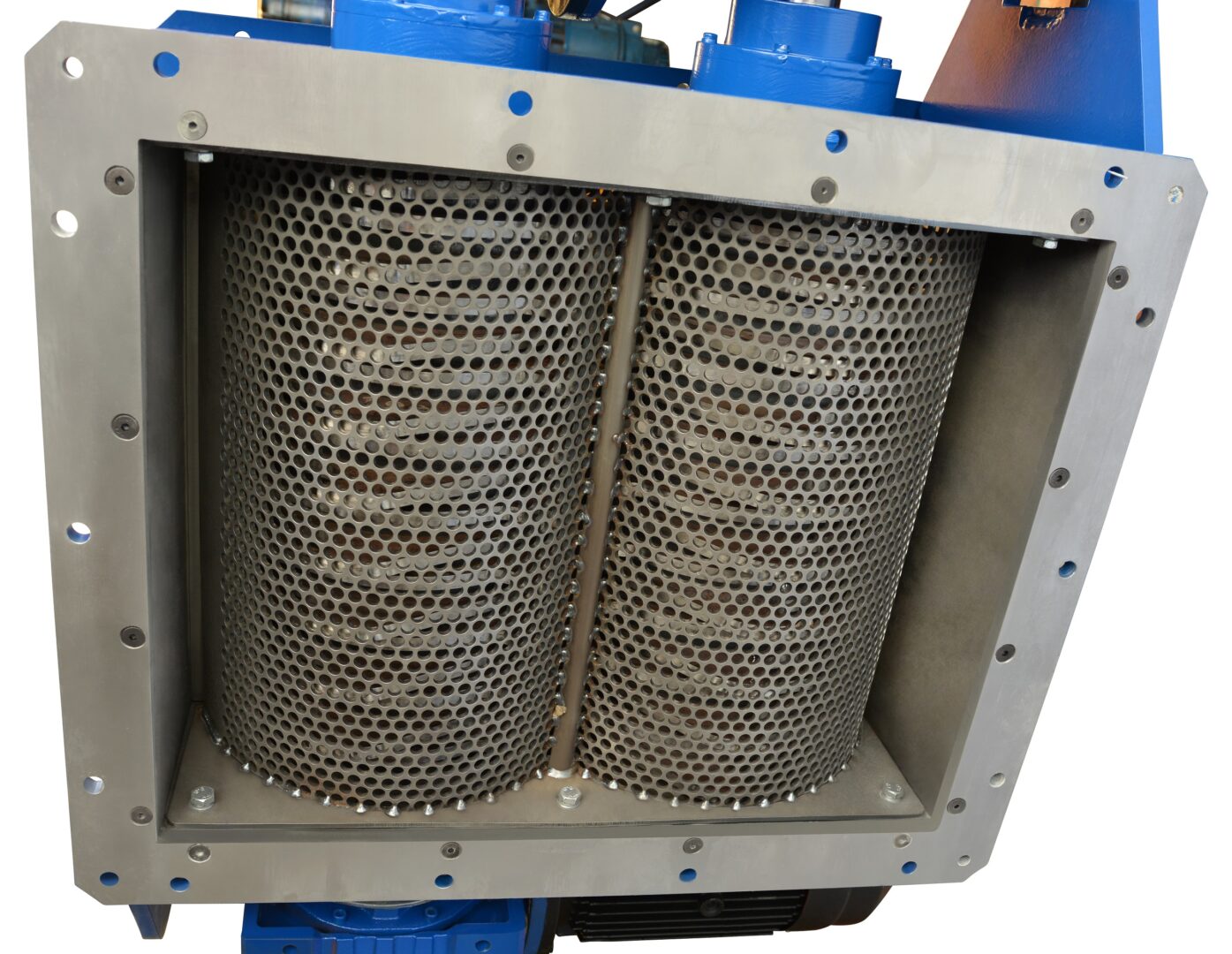

- A sieve placed underneath the rolls ensure that only ‘small enough’ particles exit the shredder.

What does it do?

The Twin Roll Shredder (TRS) is designed for durable schredding of semi-hard bulk material like coal, coke, cement clinker, limestone, gypsum etc.

How does it do it?

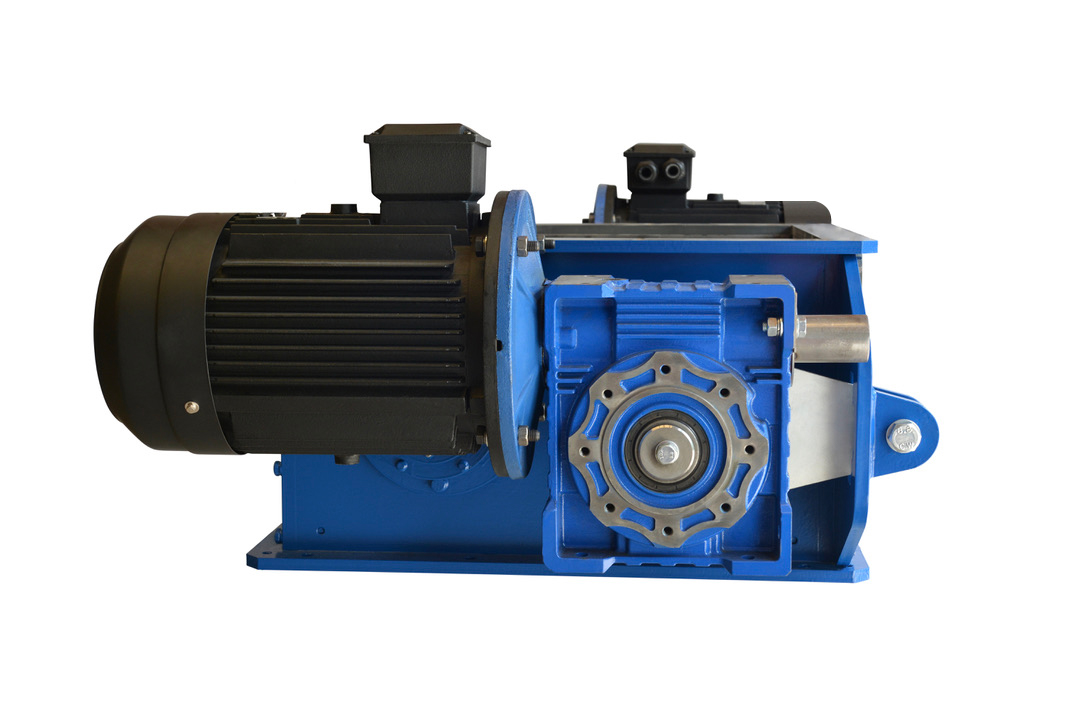

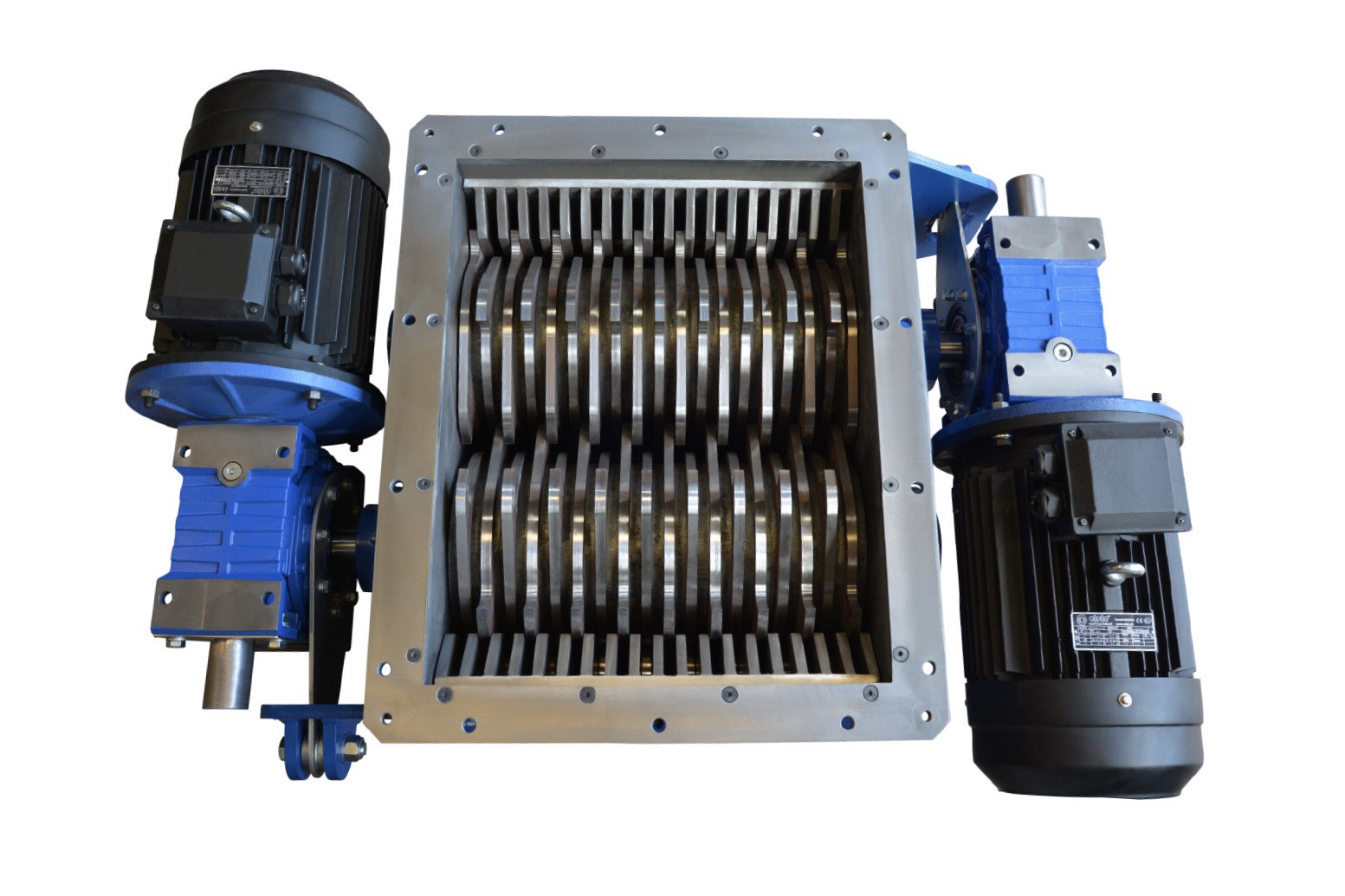

The TRS consists of an inlet opening, two counter-rotating rollers each with independent gear driven motors and a base frame. The material is fed by gravity into the top inlet opening, from where it is drawn into the shredding zone, by the two counter-rotating rollers. The twin rolls can be driven individually or synchronously controlled. To ensure that only small enough particle exits the unit a sieve is placed underneath the rolls. If a particle can not exit the hole in the sieve, it is being forced back into the inlet of the counter-rotating rollers.

The design ensures a unique self-cleaning action.

What are the technical details?

Details to follow..

Options

The rollers come in a variety of geometries equipped with bigger or smaller hooks. The roll geometry and rotation speed can be configured depending on the specific material requirements.