Vertical Disc Divider (VDD).

What’s the benefit?

- Particularly useful for small and fixed division ratio.

- Suitable for bulk material with relatively large particle sizes.

- Easy to install and operate.

- Low maintenance costs.

What does it do?

The Vertical Disc Divider (VDD) is designed for representative division of bulk material at a small and fixed division ratio.

How does it do it?

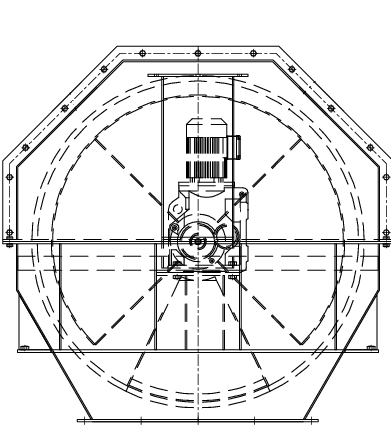

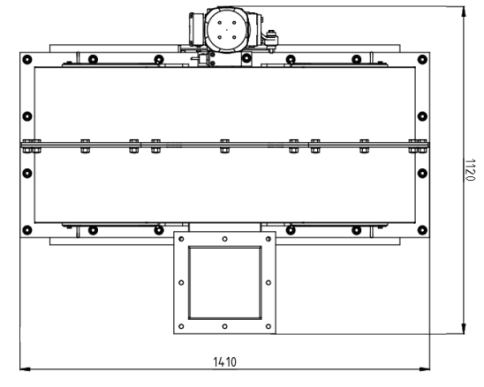

The VDD consist of a drive unit, a dividing disc and a vertical wall that separate the housing into two halves. The first half consists of the inlet chute at the top, two inspection hatches and a reject outlet in the bottom. The second half consists of the sample outlet which also has two inspection hatches.

Material is fed into the VDD through the inlet chute, directing the stream to hit a rotating vertical disc, which has a radial cutter opening (radial w.r.t. the disc shaft). The material feeding into the divider either passed through the cutter opening leading it into the second half of the housing (sample outlet) or is reflected by the moving disc and led through the bottom reject outlet.

What are the technical details?

Details to follow..

Options

The M&W central control cabinet can exchange signals with the client’s control system.

Nota Bene 1

VDD is advantageously used to perform representative division of bulk material at a low division rate.